PolyCycl's Recycling Tech Tackles Plastic Waste

Chandigarh-based startup PolyCycl launches its patented chemical recycling technology to convert hard-to-recycle plastics into food-grade polymers, renewable chemicals, and sustainable fuels.

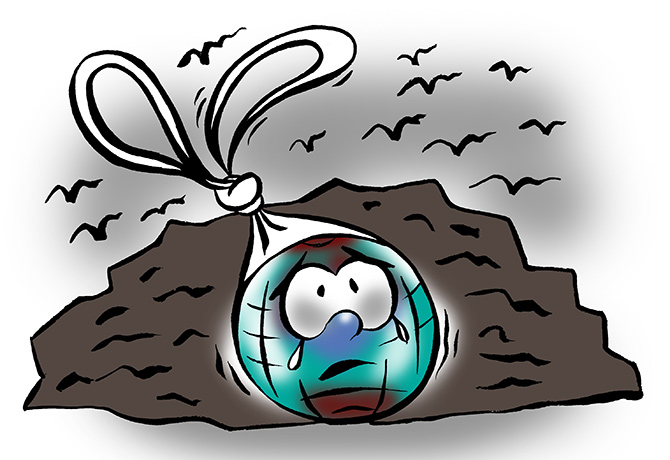

Illustration: Uttam Ghosh/Rediff.com

Chandigarh, Jan 30 (PTI) Chandigarh-based startup PolyCycl on Thursday said it has launched its patented chemical recycling pyrolysis technology aimed at addressing the plastic waste problem.

This fully-indigenous innovation enables the conversion of hard-to-recycle plastics -- such as single-use grocery bags and food-contaminated packaging, into food-grade polymers, renewable chemicals and sustainable fuels, a company statement said.

"This combination transforms low-grade plastics into liquified hydrocarbon oils, which are then purified to remove contaminants like halogens and hetero-atoms. The resulting chemical feedstocks are versatile raw materials used by the petrochemical and hydrocarbon industries to produce a wide range of premium low-carbon materials, including circular polymers," said the company.

The Generation VI chemical recycling pyrolysis technology facilitates the creation of a plastic-to-plastic circular economy, where commonly used plastics no longer need to be down-cycled, incinerated or landfilled at the end of their life. Instead, they can be continuously recycled in a closed-loop, without any loss of quality, the company said.

"India generates over 10.2 million tonnes of plastic waste annually, with more than 40 per cent of this being single-use plastics like grocery bags and flexible packaging. Traditional recycling methods struggle to handle this waste, which often ends up clogging drains, littering streets, or polluting waterways," said Amit Tandon, founder and CEO of PolyCycl.

Tandon further said "our technology, honed over a decade of research and development, delivers high conversion yields of 65-75 per cent and generates chemical feedstocks that have been qualified for the circular economy by multiple petrochemical companies globally".

This fully-indigenous innovation enables the conversion of hard-to-recycle plastics -- such as single-use grocery bags and food-contaminated packaging, into food-grade polymers, renewable chemicals and sustainable fuels, a company statement said.

"This combination transforms low-grade plastics into liquified hydrocarbon oils, which are then purified to remove contaminants like halogens and hetero-atoms. The resulting chemical feedstocks are versatile raw materials used by the petrochemical and hydrocarbon industries to produce a wide range of premium low-carbon materials, including circular polymers," said the company.

The Generation VI chemical recycling pyrolysis technology facilitates the creation of a plastic-to-plastic circular economy, where commonly used plastics no longer need to be down-cycled, incinerated or landfilled at the end of their life. Instead, they can be continuously recycled in a closed-loop, without any loss of quality, the company said.

"India generates over 10.2 million tonnes of plastic waste annually, with more than 40 per cent of this being single-use plastics like grocery bags and flexible packaging. Traditional recycling methods struggle to handle this waste, which often ends up clogging drains, littering streets, or polluting waterways," said Amit Tandon, founder and CEO of PolyCycl.

Tandon further said "our technology, honed over a decade of research and development, delivers high conversion yields of 65-75 per cent and generates chemical feedstocks that have been qualified for the circular economy by multiple petrochemical companies globally".

You May Like To Read

TODAY'S MOST TRADED COMPANIES

- Company Name

- Price

- Volume

- Vodafone Idea L

- 8.00 (+ 0.25)

- 81759037

- Suzlon Energy Ltd.

- 60.05 (+ 1.28)

- 15602971

- Softrak Venture Inv

- 3.39 (+ 2.11)

- 13286458

- YES Bank Ltd.

- 18.48 ( -1.18)

- 13250316

- Standard Capital

- 0.48 ( -2.04)

- 12448734

© 2025 Rediff.com India Limited. All rights reserved.

© 2025 Rediff.com India Limited. All rights reserved.